Wending Technology

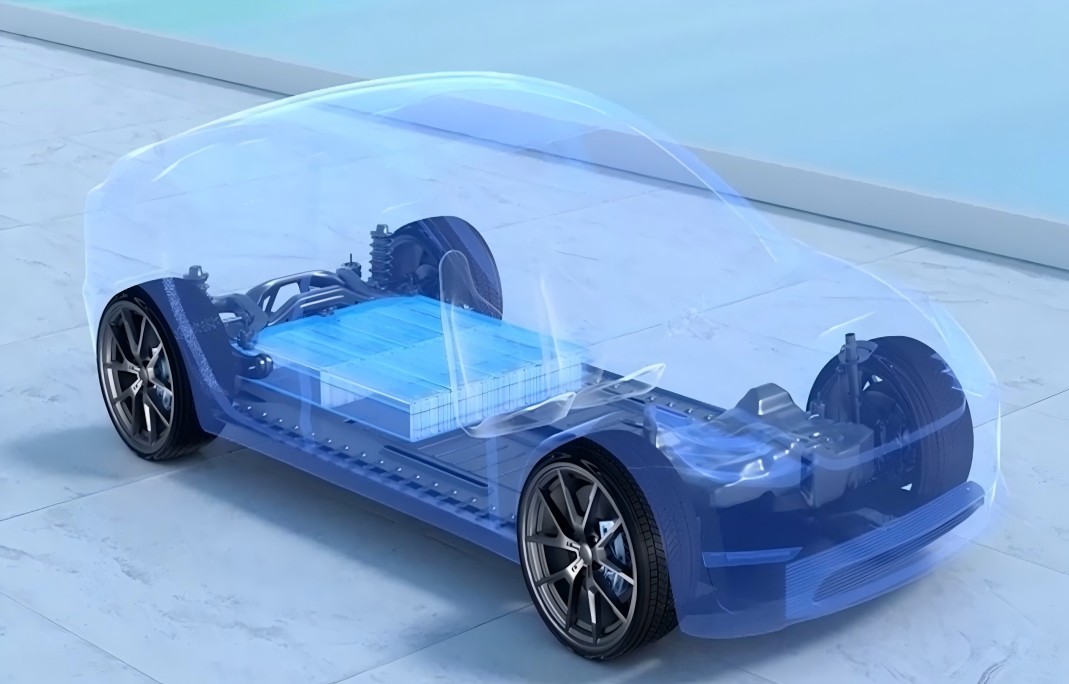

Innovative and sophisticated design, extreme space utilization, and zero tab redundancy.

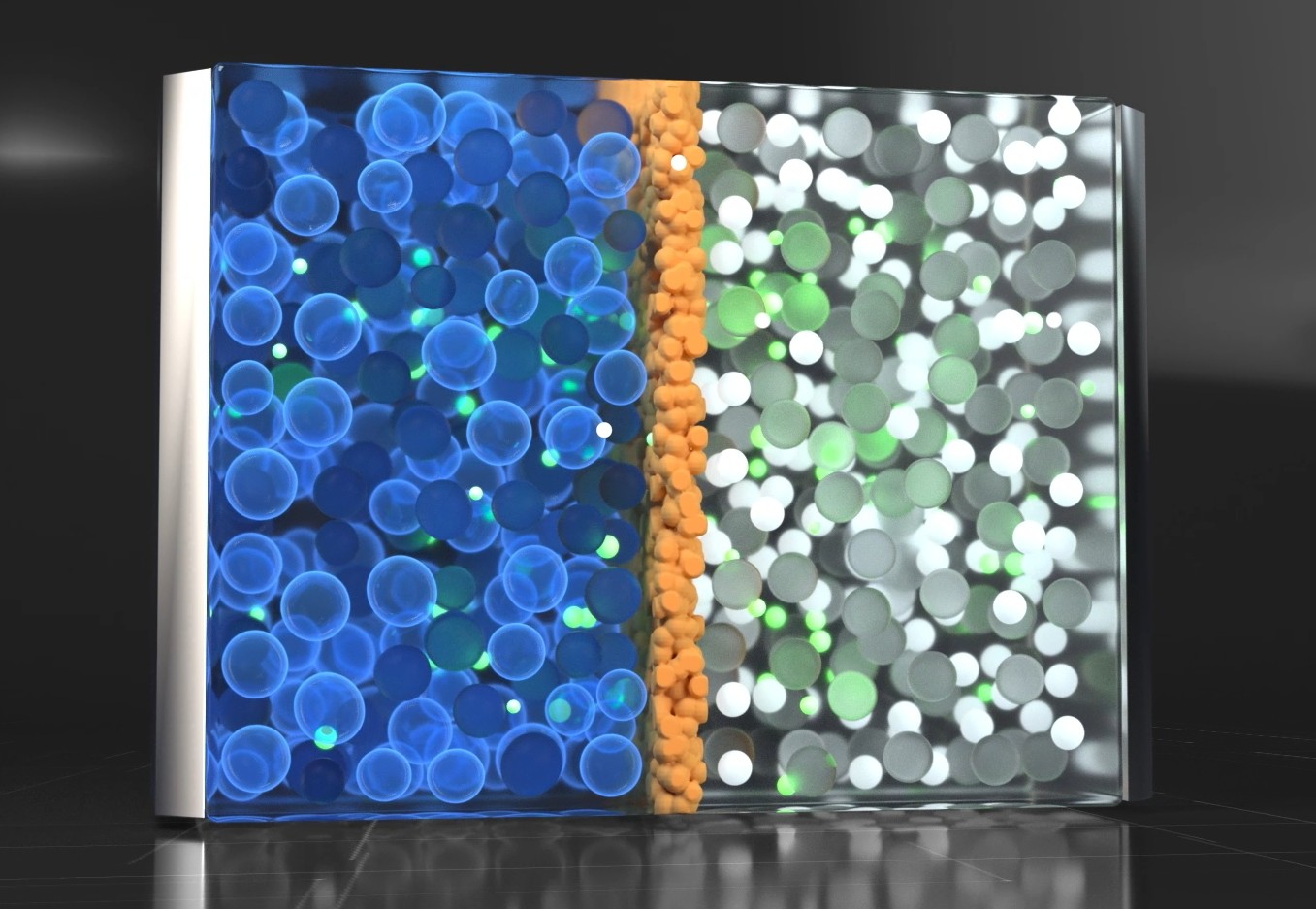

The first integrated cover design effectively improves space utilization by more than 7%; the use of dual high-solid-liquid interface technology achieves a volume energy density that breaks through the industry ceiling.

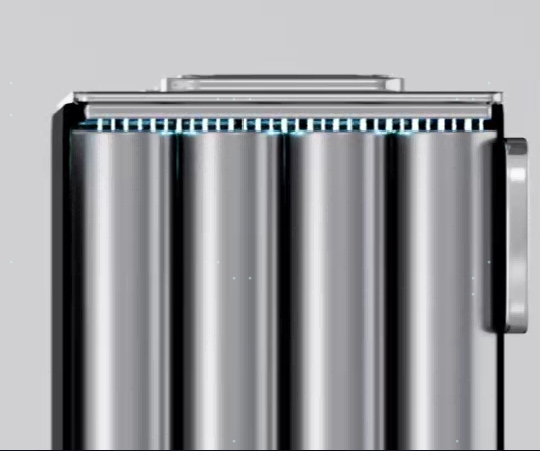

Wending Battery Structure

TraditionalBattery Structure

Through technological innovation, REPT BATTERO has tightly connected the battery core and the cover plate, without U-shaped bends in the tabs, and has compressed the top space inside the battery cell to form a highly stable structure, effectively increasing space utilization by more than 7%.

After the tab is bent, it is conductively connected to the adapter on the upper surface of the adapter, avoiding the short circuit risk caused by tab redundancy, sinking, and different relaxation states, and can improve the performance and service life of the battery.

This measure brings three major benefits: there is no U-shaped bend, forming a highly stable structure; the length of the pole ear is shortened by 50%, bringing super current capacity; the core space utilization is improved, and the volume energy density is increased by more than 10%.

In terms of product design, we adhere to the design concept of high surface density and high compaction, and focus on the multi-dimensional solid-liquid interface design technology of double-high design. Through non-destructive detection technology and simulation technology, we conduct in-depth research and construction of multi-dimensional pore structure, achieve breakthroughs in infiltration technology, and make the solid-liquid interface achieve a perfectly controllable state.

High efficiency, high safety, long life and other performance upgrades

Under the LFP system, Wending Technology has currently achieved a volume energy density of 450Wh/L; under the NCM system, it can reach a volume energy density of 650Wh/L.

Thanks to the excellent compatibility of the "Wending" technology, it is widely compatible with various types of square aluminum shells and long batteries, lithium iron phosphate and ternary lithium battery products.

In terms of products, taking the Wending 175AH power battery cell as an example, compared with the 166AH battery cell, its capacity has increased by 6%, the volume utilization rate has increased by 7%, and the DC internal resistance has decreased by 10%, which can achieve a vehicle range of 700KM.

If it is used in an energy storage power station scenario, taking the Wending 320AH energy storage cell as an example, it can achieve the effect of reducing system costs by 15%, reducing floor space by 15%, and increasing return on investment by 10%.